Flame safety monitoring solution for heating furnace

1. Background and meaning

Petrochemical heating furnace is used for high-temperature reaction and high-temperature heating equipment. It has the characteristics of high risk, direct fire heating, and long operating cycle. As the country attaches importance to the safety of petrochemical production, the visualization of furnace combustion has become an indispensable condition in the petrochemical process. Its main functions are:

● Monitor the flame status of the burner to prevent hidden dangers of production accidents caused by flame extinguishing or partial burning ;

● Real-time monitoring of the furnace tube and furnace lining status to achieve planned maintenance.

2, plan

Heating furnace flame safety monitoring solution system structure consists of explosion-proof high temperature probe, explosion-proof control box, gas circuit control cabinet, decoding and display equipment, according to the different distribution of furnace burners (such as hydrogen production The furnace generally adopts the top-fired type, and the ethylene cracking furnace generally adopts the bottom-fired type), and the probe matching the process is used to realize the real-time monitoring of the combustion status of the furnace. This solution has automatic control of the advance and retreat of the local probe, remote control of the advance and retreat of the probe, and self-checking of the probe, signal output, data stream standard output and other functions.

3, value

● Real-time monitoring of the internal operating status of the heating furnace, reducing production safety hazards, and improving the stable operation cycle of the furnace ;

● Design products according to the scene, realize multi-location, large area, high-definition monitoring, ensure that you can see See, see clearly, use long;

● Reduce manual inspections, reduce workload, and improve employees’ occupational health.

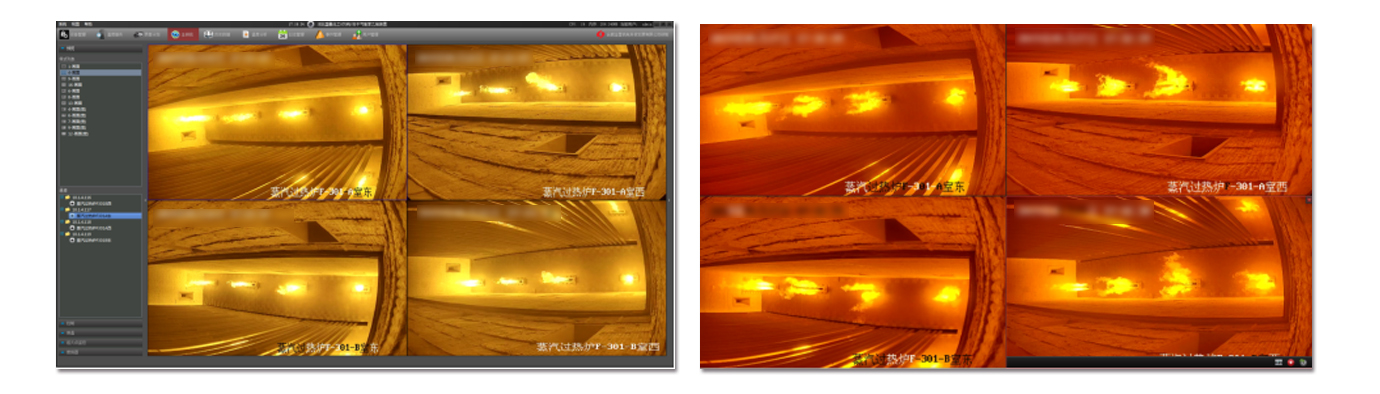

4. Application case

更多案例

Consult now

If there is any need, we will arrange personnel to contact you as soon as possible

CONTACT US

Address: No. 228, Wanshui Road, High-tech Zone, Hefei City, Anhui Province

Hotline:400-805-8899

Service line:800-868-2578

Tel:0551-65324828

Scan and follow us

Copyright © 2021 Hefei Glod Star M&E Technical Development Co.,Ltd 皖ICP备05013787号-2

400-805-8899

400-805-8899

点击咨询

点击咨询