Solution for online monitoring of combustion temperature field in a combustion chamber

1. Background and meaning

The main treatment method of hazardous waste is rotary kiln incineration. The temperature of the bottom slag mouth and the central flame zone at the end of the rotary kiln is of great significance to the optimization and control of the incineration process of the rotary kiln. Traditional The method of obtaining the temperature of the flame zone at the end of the kiln is achieved through manual experience or the installation of a point-type thermometer. The main problems are:

● Manual experience judgment is affected by subjective factors, and it is difficult to guide the kiln operator to fine control;

● Single-point temperature measurement cannot determine the temperature measurement location, and it is difficult to achieve precise location temperature measurement.

2, plan

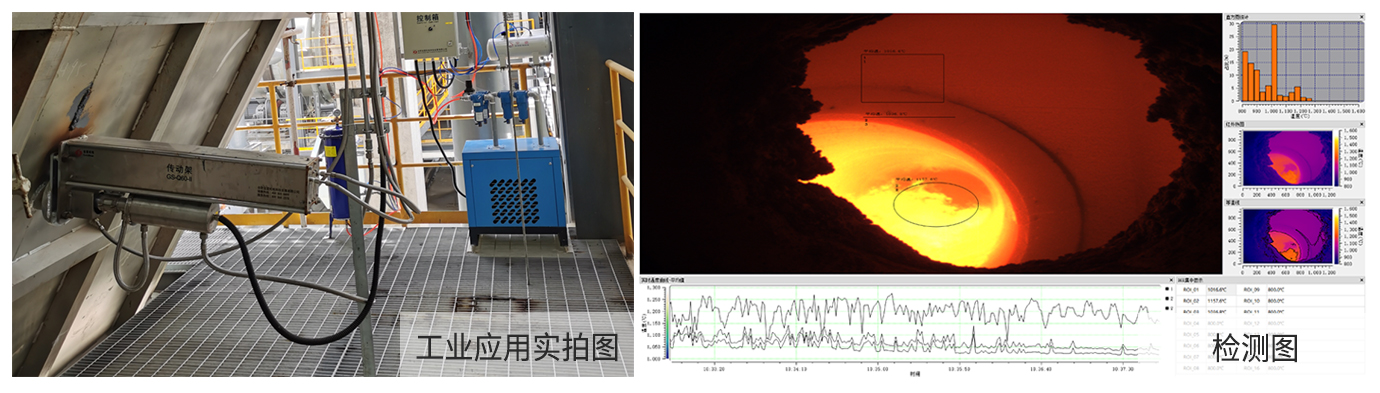

On-line monitoring of combustion temperature field in a combustion chamber Solution The system structure is mainly composed of multi-spectral imaging probe, control box, server and display terminal. Based on the center of the kiln end of a combustion chamber and the thickness of the furnace wall, the structure adopts the imaging and transmission split direct-view probe to increase the reach of the probe into the furnace. Internal effective length, this set of solutions is based on the principle of black body radiation and dual-light fusion, colorimetric temperature measurement technology through the front-end multi-spectral camera to collect visible light and near-infrared spectrum signals and output video data stream and temperature data stream, the back end uses special software For displaying real-time video and two-dimensional temperature field, the software has functions such as ROI temperature analysis, infrared heat map analysis, and histogram temperature analysis.

3, value

● Non-contact temperature measurement, long service life of the equipment, reduce the cost of manual inspection, and increase the economic benefits of the enterprise;

● Wide temperature measurement range, high temperature measurement accuracy, integrated video and temperature field display, convenient for real-time guidance of process control.

4. Application case

更多案例

Consult now

If there is any need, we will arrange personnel to contact you as soon as possible

CONTACT US

Address: No. 228, Wanshui Road, High-tech Zone, Hefei City, Anhui Province

Hotline:400-805-8899

Service line:800-868-2578

Tel:0551-65324828

Scan and follow us

Copyright © 2021 Hefei Glod Star M&E Technical Development Co.,Ltd 皖ICP备05013787号-2

400-805-8899

400-805-8899

点击咨询

点击咨询