Solution for online detection of molten steel temperature in refining furnace

1. Background and meaning

VD furnace is a ladle refining furnace, which deoxidizes, desulfurizes and removes hydrogen by blowing argon under vacuum to achieve steel refining The purpose of the temperature control of molten steel in the refining process is of great significance to improve the level of process control and ensure the quality of molten iron. Traditional temperature measurement methods can only be used to measure temperature by manual thermocouples before and after entering the furnace. The main problems are:

● There are many sampling times, and the labor intensity of personnel is high;

● Blowing temperature monitoring cannot be achieved, and temperature measurement has hysteresis;

● The temperature of molten steel is high, the environment is harsh, and the personnel risk factor is high.

2, plan

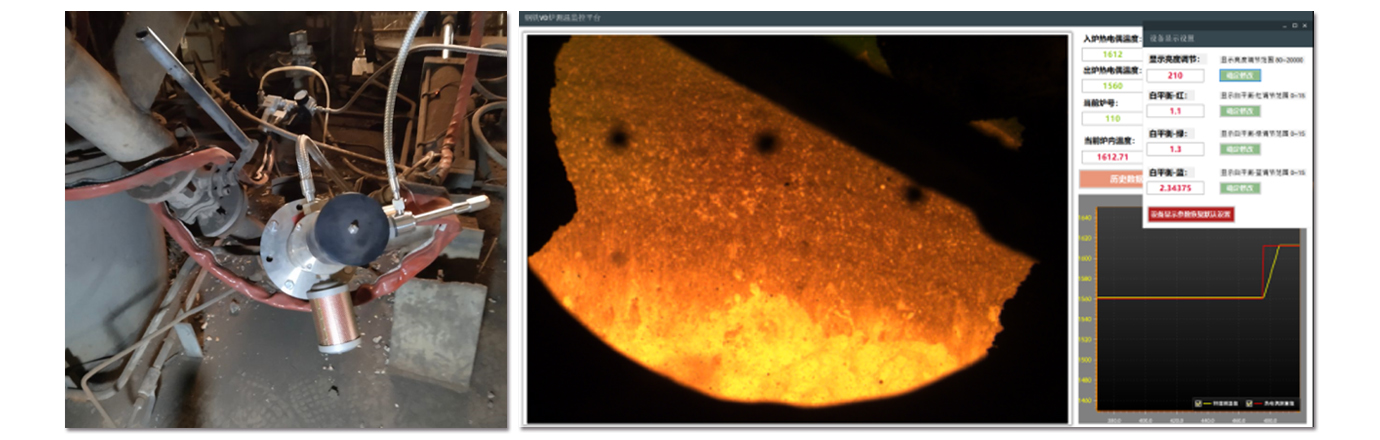

Refining furnace molten steel temperature online detection solution is mainly composed of multi-spectral imaging temperature probe, control box, server and display terminal. According to the thickness of the refining furnace cover and the requirements for sealing, fixed imaging temperature probe is used to improve the system sealing This set of solutions is based on the principle of black body radiation, dual-light fusion, and colorimetric temperature measurement technology. The front-end multi-spectral camera collects visible light and near-infrared spectrum signals and outputs video data streams and temperature data streams. The back-end uses dedicated software for display Real-time video and two-dimensional temperature field, the software has ROI temperature analysis, infrared heat map analysis, historical record query and other functions.

3, value

● Real-time monitoring of the internal operating status of the heating furnace, reducing production safety hazards, and improving the stable operation cycle of the furnace;

● Design products according to the scene, realize multi-position, large area, high-definition monitoring, ensure that you can see, see clearly, and use it for a long time;

● Reduce manual inspections, reduce labor intensity, and improve employees' occupational health.

4. Application case

更多案例

Consult now

If there is any need, we will arrange personnel to contact you as soon as possible

CONTACT US

Address: No. 228, Wanshui Road, High-tech Zone, Hefei City, Anhui Province

Hotline:400-805-8899

Service line:800-868-2578

Tel:0551-65324828

Scan and follow us

Copyright © 2021 Hefei Glod Star M&E Technical Development Co.,Ltd 皖ICP备05013787号-2

400-805-8899

400-805-8899

点击咨询

点击咨询