|

Module name

|

Features

|

Value

|

|

Workshop overview

|

Comprehensive display of workshop production management data

|

Let workshop managers fully control the real-time production, energy, equipment, quality and other key data of the workshop

|

|

Bronze management

|

Display and count the copper output data of all cell groups in the electrolysis workshop by shifts and groups

|

Let the managers have a complete grasp of the copper output in the workshop, and the copper output data can be counted and traced.

|

|

Short circuit management

|

The short-circuit management module comprehensively displays the abnormal conditions of the workshop plate short-circuit, hot burning, cold burning, etc., records the processing process, and counts the short-circuit situation

|

The short-circuit situation of the plates in the production process can be fully controlled, which has guiding significance for process improvement

|

|

Energy Management

|

Energy data access and statistics, comprehensive display of electricity consumption, water consumption, steam consumption, etc. of the electrolysis workshop

|

Make the energy consumption data of the electrolysis workshop clear at a glance, and provide data support for the optimization of energy saving in electrolysis production

|

|

Quality Management

|

Calculation and analysis of stripping speed, excellent product rate, statistics and trend graph display

|

Establish a quality management system to promote production quality improvement

|

|

Overhaul management

|

Show the status of the electrolytic cell, edit the state of the electrolytic cell

|

Improve the digital management level of the workshop and improve the efficiency of production management

|

|

Job sequence management

|

Calculation and analysis of residual pole rate and slot utilization rate, statistics and trend graph display

|

Analyze and calculate key data to provide a basis for subsequent production optimization and production evaluation

|

|

Performance management

|

Access to workshop performance data, statistics and display of workshop cost data

|

Form a standardized performance appraisal mechanism, reduce tedious report filling, and improve management energy efficiency

|

|

Asset management

|

Fixed asset management, spare parts direct consumable management

|

Lightweight and practical workshop-level asset management system, standardize the use of consumables and reduce costs

|

|

APP

|

The functions of the intelligent information management system of the electrolysis workshop are extended to mobile devices

|

Let workshop managers control the dynamics of workshop operation anytime and anywhere, flexible and convenient

|

|

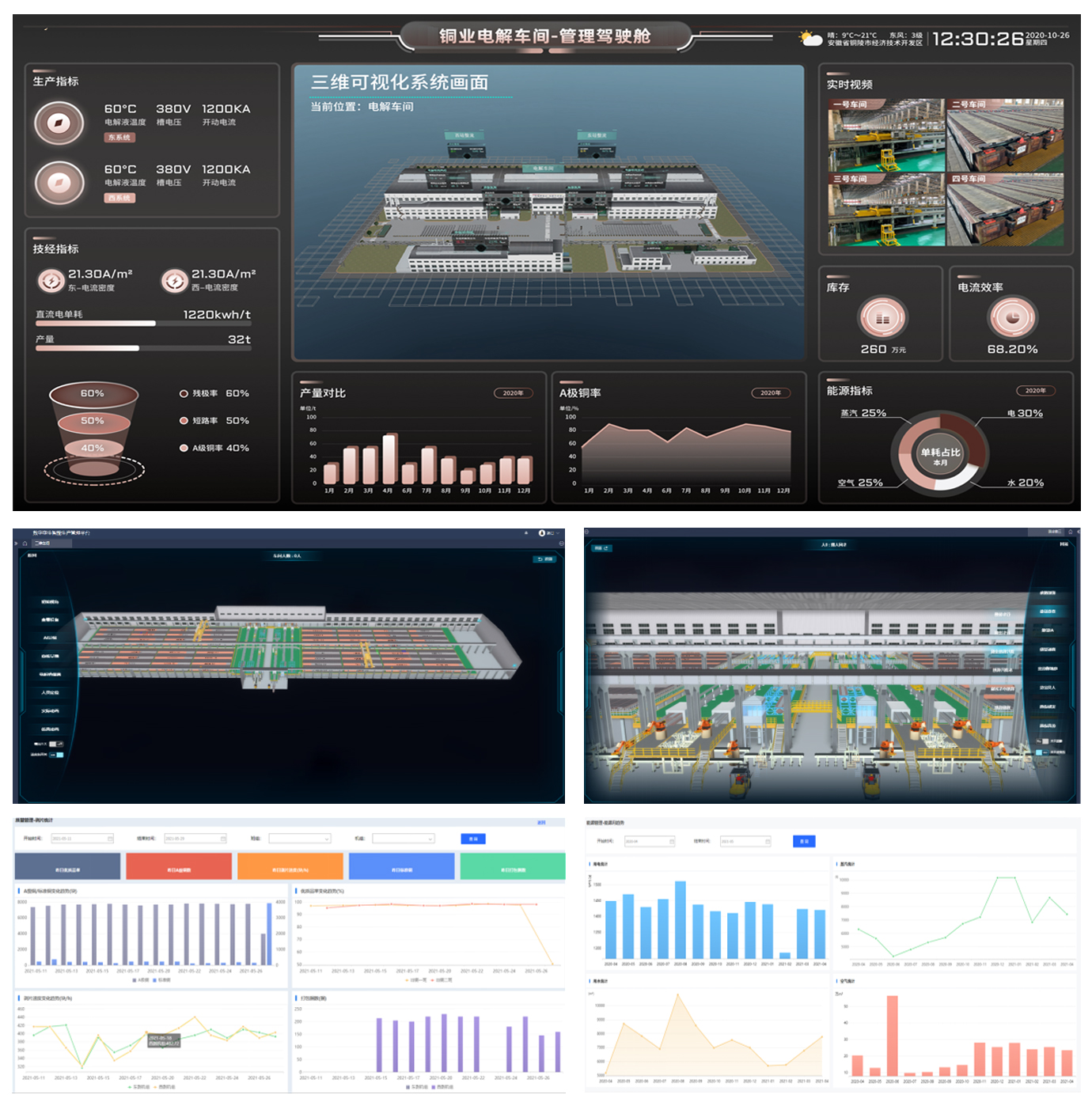

Manage the cockpit (large screen system)

|

Build a big data center for the workshop, and display the important production management data of the workshop in a cool way

|

The foundation of high-level data analysis, provides data support for workshop production optimization, and 3D virtual simulation gives customers a new experience of high-end intelligence

|

400-805-8899

400-805-8899

点击咨询

点击咨询