产品中心

GS-IRAT2300 infrared thermal imaging thermometry and analysis system

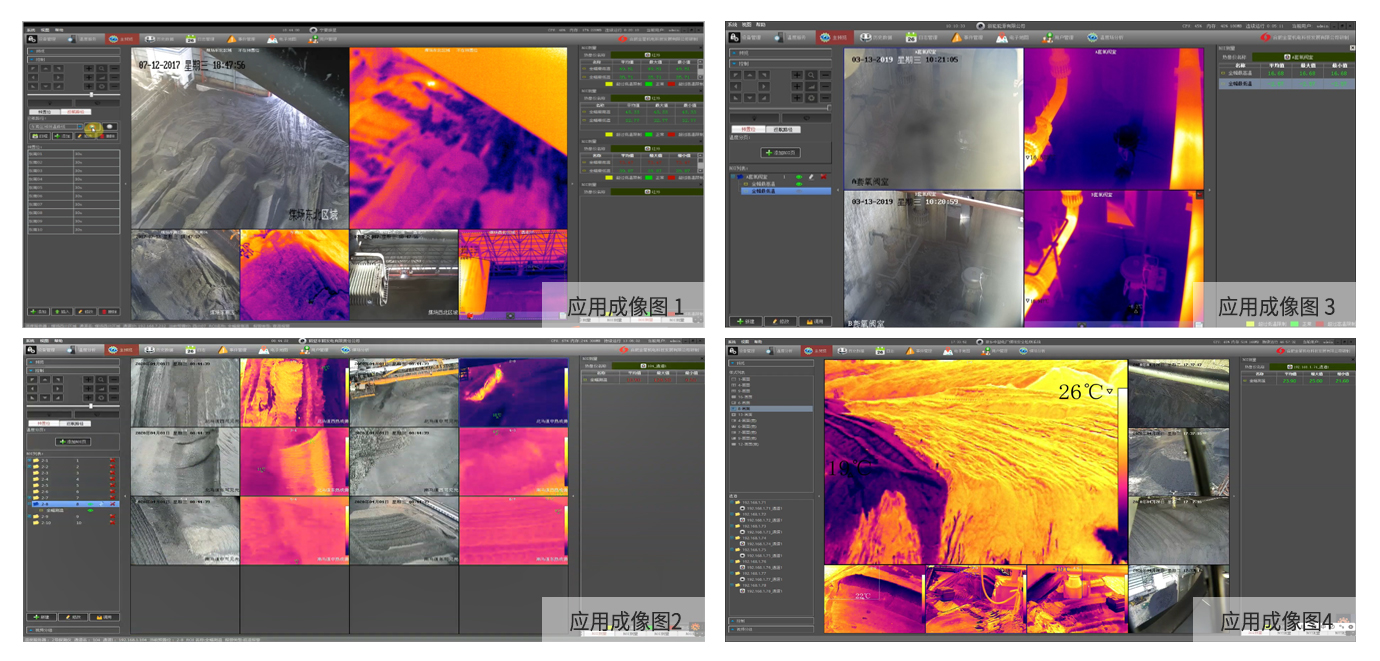

The GS-IRAT2300 infrared thermal imaging thermometry and analysis system is a real-time monitoring system integrating visible light, infrared thermal imaging and embedded processing technology. The system can analyze the acquired visible light video and infrared thermal images to accurately detect the measured target Surface temperature change and hot spot distribution, detect and analyze the temperature change trend, find hidden danger points of temperature abnormality, and automatically generate corresponding temperature change reports. When the temperature exceeds the set threshold, the system can output an alarm signal to achieve target monitoring The temperature status information monitoring of the area achieves the functions of thermal fault warning and defect judgment.

Relative Products

CONTACT US

Address: No. 228, Wanshui Road, High-tech Zone, Hefei City, Anhui Province

Hotline:400-805-8899

Service line:800-868-2578

Tel:0551-65324828

Scan and follow us

Copyright © 2021 Hefei Glod Star M&E Technical Development Co.,Ltd 皖ICP备05013787号-2

400-805-8899

400-805-8899

点击咨询

点击咨询