产品中心

GS-IRAT2200 furnace combustion infrared thermometry system

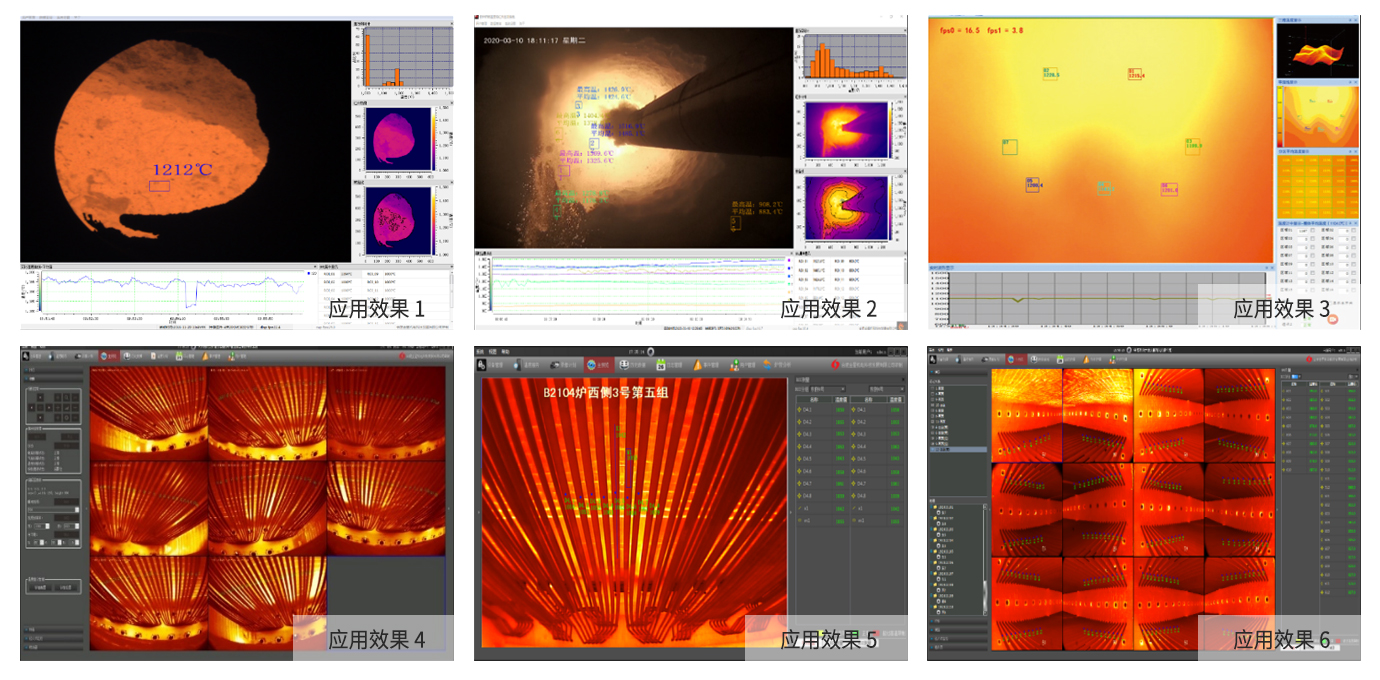

GS-IRAT2200 furnace combustion infrared thermometry system is an endoscopic split imaging temperature measurement system applied to various types of industrial furnaces. The system can not only realize the color video monitoring of the combustion conditions in the kiln, but also can simultaneously detect the temperature of any area of interest in the field of view. It provides intuitive and reliable detection methods for industrial furnaces to optimize combustion, save energy and reduce emissions, and improve combustion efficiency. It has been widely used in petrochemical, electric power, cement, metallurgy and other industries.

Relative Products

CONTACT US

Address: No. 228, Wanshui Road, High-tech Zone, Hefei City, Anhui Province

Hotline:400-805-8899

Service line:800-868-2578

Tel:0551-65324828

Scan and follow us

Copyright © 2021 Hefei Glod Star M&E Technical Development Co.,Ltd 皖ICP备05013787号-2

400-805-8899

400-805-8899

点击咨询

点击咨询