Online detection solution for spontaneous combustion prevention of garbage pits and temporary storage warehouses

1. Background

The basic treatment steps of hazardous waste include classification, pretreatment, and final disposal. Metals, greases, solvents, dyes and other wastes that are valuable for recycling can be recycled; pretreatment includes physical and chemical methods, and the hazardous waste after pretreatment can enter the final disposal facilities such as incineration or landfill. Cement kiln co-processing hazardous waste in the cement industry means that hazardous waste that meets or meets the requirements for entering the kiln (grinding) after pretreatment is put into the cement kiln or cement mill. While clinker or cement is produced, the hazardous waste is treated at the same time. The process of harmless disposal, cement kilns can dispose of hazardous wastes and household garbage. According to the different types, shapes and characteristics of hazardous waste, it is classified and stored as required. Part of the hazardous waste directly enters the pit to mix, and the other part enters the temporary storage warehouse or waste liquid storage tank, and hazardous waste storage. Hazardous waste is poisonous, corrosive, flammable, explosive, etc., which are likely to cause serious harm to the ecological environment and human safety. The management and monitoring of toxic and hazardous substances in pits and temporary storage has become very important. Existing monitoring methods are generally divided into manual inspections and visible light monitoring. The main problems are:

● Manual inspection characterized by high cost, low efficiency, high risk factor, and judgment results are easily subject to personal experience.

● Visible light monitoring can only detect smoke and flames when a fire occurs, and cannot meet the requirements for pre-warning of spontaneous combustion and fire.

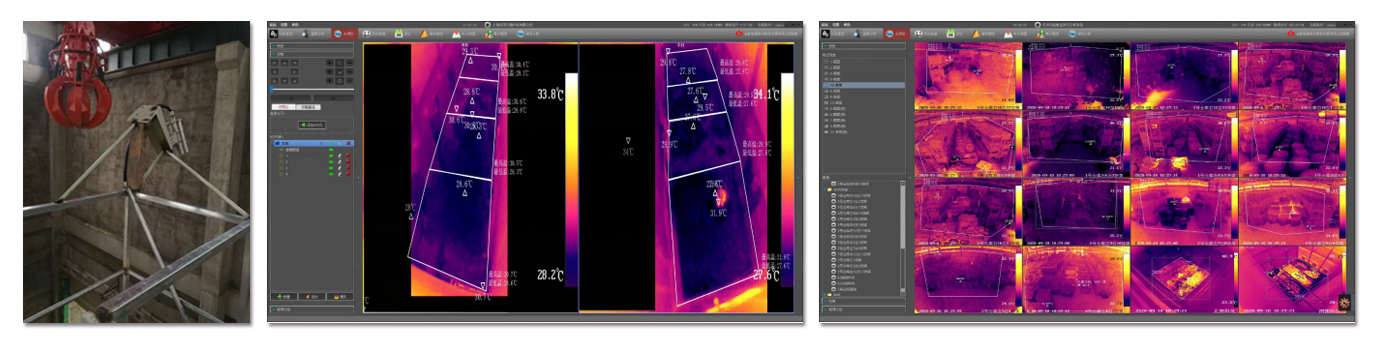

2, plan

The project uses the GS-IRAT2300 IR thermal imaging termometry and analysis system. The IR scanner set up on the top of the material pit and the temporary storage warehouse performs 24-hour real-time inspections of the material pit and temporary storage warehouse to obtain IR images within its field of view and locate abnormal temperature targets with comprehensive observation and analysis. The IR analysis processing program in the backend determines whether the alarm threshold is reached by analyzing the real-time infrared thermal image. If the alarm value is exceeded, the control end of the monitoring room can realize the sound and light alarm in parallel with the local fire sprinkler device.

3. Main functions

● Based on fully digital instruments and equipment, using IPVS and advanced network technology to achieve all-weather infrared imaging And temperature monitoring;

● According to the set monitoring target, use the infrared thermal imager to collect the infrared image of the current target, get the current temperature of the target surface;

● According to the preliminary diagnosis of the collected infrared images, the current temperature information of the target is obtained, and in the case of potential hazards, audible and visual alarm signals are given.

4. Value

● 7× 24-hour real-time monitoring of the safe storage of hazardous waste in the pit and temporary storage to ensure safe production;

● Design products according to the scene, realize multi-location, large area, high-definition monitoring to ensure better viewing with long service hours;

● Reduce manual inspections, reduce work, prevent toxic and harmful substances from harming the human, and improve employee occupational health;

● Fire prevention before “combustion”, you can find safet hazards in the early stage of the fire. Early warning to avoid accident escalation;

● According to the risk level, set up multi-level alarms, support alarm linkage with fire-fighting facilities, and reduce losses.

4. Application case

更多案例

Consult now

If there is any need, we will arrange personnel to contact you as soon as possible

CONTACT US

Address: No. 228, Wanshui Road, High-tech Zone, Hefei City, Anhui Province

Hotline:400-805-8899

Service line:800-868-2578

Tel:0551-65324828

Scan and follow us

Copyright © 2021 Hefei Glod Star M&E Technical Development Co.,Ltd 皖ICP备05013787号-2

400-805-8899

400-805-8899

点击咨询

点击咨询