GS-LIBS2100 Laser Composition Analyzer

GS-LIBS2100 laser composition analyzer is an offline composition analysis system for rapid detection of material composition in front of the furnace or in the analysis laboratory. The system has built-in gas purging, dust removal in the removable bin, laser auto-focusing, local/remote one-key operation, detection point path planning and high-resolution imaging functions. It can quickly realize high-precision detection of material components without sample pretreatment.

GS-LIBS2200 Laser Composition Analyzer

GS-LIBS2200 laser composition analyzer is an online composition analysis system for rapid detection of high temperature melt, solid or powder material composition. The system adopts independent design of detection probe and control cabinet, built-in automatic detection distance control, dust and smoke protection, automatic temperature adjustment, local/remote one-key operation and other functions, which can quickly realize long-distance high-precision detection of material components.

GS-LIBS2500 laser composition analyzer

GS-LIBS2500 laser composition analyzer is an online composition analysis system for rapid detection of the composition of materials conveyed by conveyor belts. The system adopts the integrated design of detection probe and control cabinet, built-in detection distance automatic control, dust and smoke protection, detection process material status monitoring, automatic temperature adjustment, local/remote one-key operation and other functions, which can quickly achieve long-distance high material composition Accuracy testing.

GS-IRPT2100 kiln fume Temperature Infrared Detection System

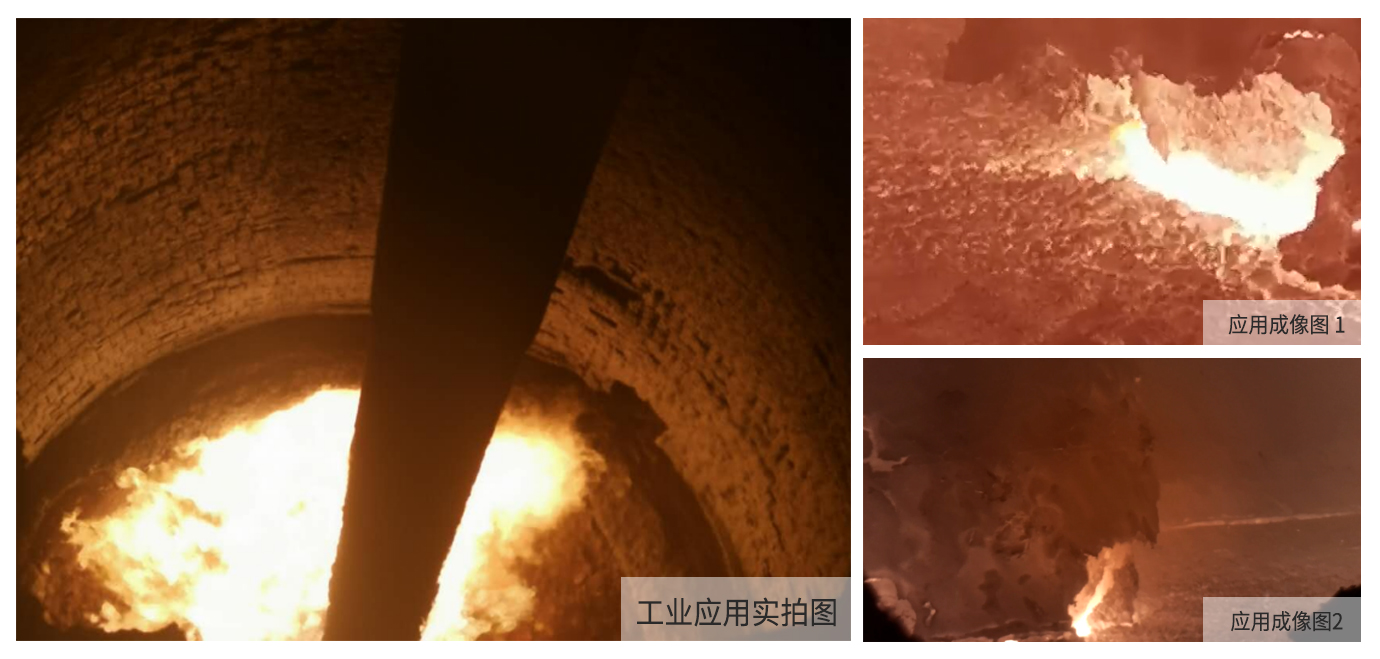

The GS-IRPT2100 kiln smoke temperature infrared detection system is a real-time online non-contact infrared temperature measurement system for high-temperature smoke and solid materials of various kilns. The system is based on Planck's blackbody radiation law combined with the emissivity of different measured targets to realize real-time online temperature monitoring, which provides a basis for operators to grasp the temperature changes of flue gas or materials in real time and improve the level of process control.

GS-IRPT2200 kiln fume Temperature Infrared Detection System

GS-IRPT2200 kiln smoke temperature infrared detection system is a real-time online non-contact infrared temperature measurement system for high-temperature smoke and solid materials of various kilns. The system is based on Planck's blackbody radiation law combined with the emissivity of different measured targets to realize real-time online temperature monitoring, which provides a basis for operators to grasp the temperature changes of flue gas or materials in real time and improve the level of process control.

GS-IRPT2300 kiln fume Temperature Infrared Detection System

The GS-IRPT2300 kiln smoke temperature infrared detection system is a real-time online non-contact infrared temperature measurement system for high-temperature smoke and solid materials of various kilns. The system is based on Planck's blackbody radiation law combined with the emissivity of different measured targets to realize real-time online temperature monitoring, which provides a basis for operators to grasp the temperature changes of flue gas or materials in real time and improve the level of process control.

GS-IRLT2200 infrared thermommetry and analysis system

GS-IRLT2200 infrared scanning temperature measurement system is used in the monitoring of kiln shell temperature of various types of industrial rotary kilns. The system uses a high-speed optical-mechanical scanning thermometer with high resolution and thermal sensitivity to accurately monitor and locate the surface temperature of the kiln carcass during the rotation period of the rotary kiln. The system performs multi-dimensional measurement based on the detected carcass surface temperature information. The analysis screen display provides reliable basis for the operators to fully grasp the surface temperature distribution of the kiln carcass and the kiln skin in the kiln in a timely manner, so as to avoid the occurrence of "red kiln" and "ring formation".

GS-IRLT2100D infrared thermometry and analysis

The core equipment of the GS-IRLT2100D infrared scanning temperature measurement system adopts a high-resolution, high-sensitivity industrial infrared thermal imager. The system can perform accurate positioning detection and real-time image analysis on the surface temperature of the kiln carcass within one revolution of the rotary kiln. Through the system to provide a wealth of analysis pictures, the operator can timely and comprehensively grasp the distribution of the kiln carcass surface temperature and the large amount of information about the kiln skin and lining carried by the kiln carcass temperature. These important information are important for the rotary kiln. The operator improves the operation of the kiln and prevents damage to the kiln lining and kiln carcass, providing an accurate and reliable operation basis.

400-805-8899

400-805-8899

点击咨询

点击咨询