产品中心

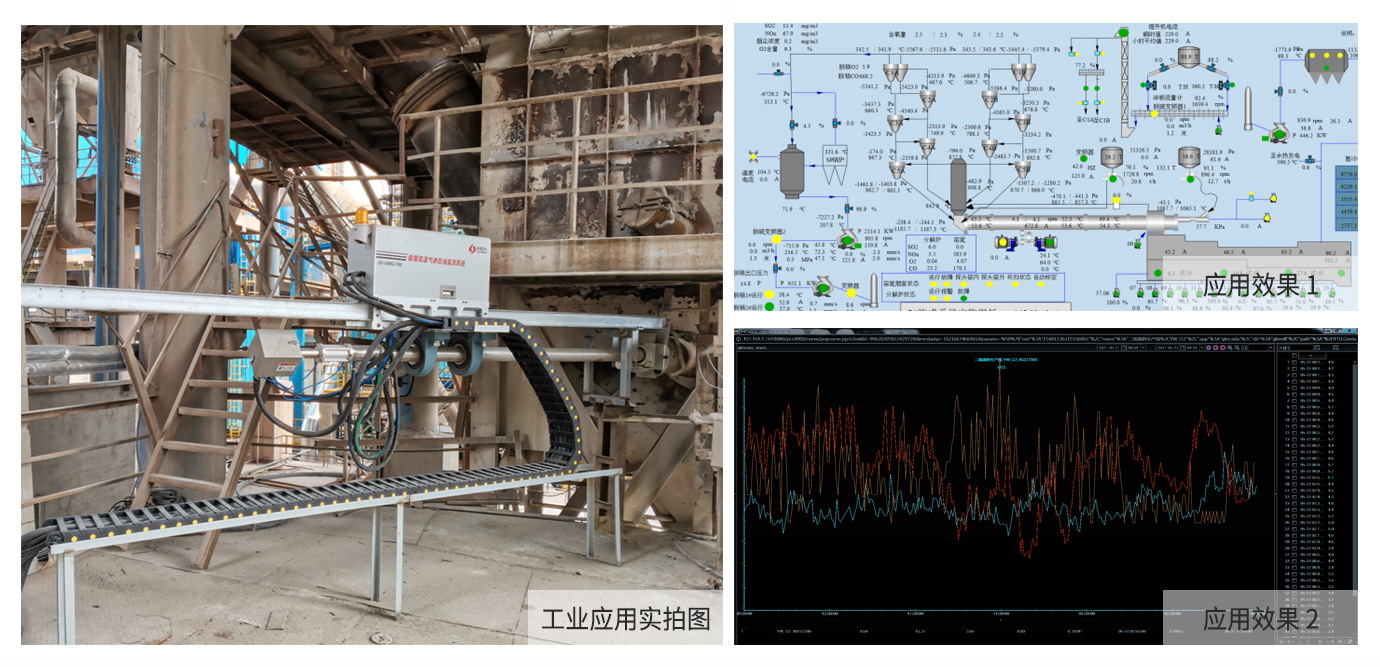

GS-GMS1700 online monitoring system for high temperature gas at kiln tail

GS-GMS1700 kiln tail high-temperature gas online monitoring system is a continuous gas detection system evolved from traditional high-temperature gas analyzer sampling device that is characterizd by high failure rate and massive maintenance. Particularly, it is suitable to detect gas in the kiln environment above 1000 ℃. As it effectively controls the flow of air and coal, and the amount of material, it could achieve accurate and reliable operation by optimizing control of the combustion process and high quality and low energy consumed production.

Relative Products

CONTACT US

Address: No. 228, Wanshui Road, High-tech Zone, Hefei City, Anhui Province

Hotline:400-805-8899

Service line:800-868-2578

Tel:0551-65324828

Scan and follow us

Copyright © 2021 Hefei Glod Star M&E Technical Development Co.,Ltd 皖ICP备05013787号-2

400-805-8899

400-805-8899

点击咨询

点击咨询