Digital comprehensive solution for intelligent electrolysis workshop

1. Background and meaning

In order to implement the "Guiding Opinions on Deepening “Internet + Advanced Manufacturing” Development of Industrial Internet", "New Generation Artificial Intelligence Development Plan", "Intelligent Manufacturing Engineering Implementation Guide (2016-2020)" and other countries Relevant policies have effectively promoted the intelligent upgrading of non-ferrous metal smelting enterprises, combined with the symbiosis of multi-element resources in non-ferrous metal smelting in China, large fluctuations in raw material quality, and complex smelting processes. The application of cutting-edge technologies such as data, artificial intelligence, 5G, edge computing, and virtual reality in non-ferrous smelting plants, especially electrolysis workshops, realizes the digital convergence, network sharing and platform collaboration of resource elements such as production, equipment, energy, and logistics. It has the ability to visualize online monitoring of all-factor data at the workshop level, real-time autonomous linkage balance and optimization, and build a green that integrates full-process automated production lines, comprehensive integrated information management and control platforms, real-time collaborative optimization, and refined energy efficiency control , safe and efficient non-ferrous metal intelligent electrolysis workshop, promote the high-quality development of workshop production, create a model "smart workshop", and enhance the company's comprehensive competitiveness and sustainable development capabilities. At present, the domestic electrolysis workshop still uses traditional manual report statistics and analysis, and lacks digital and intelligent management methods. The main problems are:

● The key process lacks intelligent quality inspection equipment, and manual inspection, eye-sight, and hand-touch methods are mainly used ;

● DCS, production management, equipment management, energy management and other systems have become data islands, lacking unified information management;

● The massive trivial data generated in various production processes are filled in and recorded by manual paper reports ; paperless work is not available yet;

● The main production process display is achieved by flow chart, and there is no virtual simulation;

● Daily management such as production task command and dispatch, operation planning, material management, etc., failed to achieve automation and visualization;

● Lack of intelligent detection, wireless industrial Ethernet, integrated information interaction, large-screen integrated display, 3D A digital integrated management platform integrating workshops and smart mobile applications.

2, plan

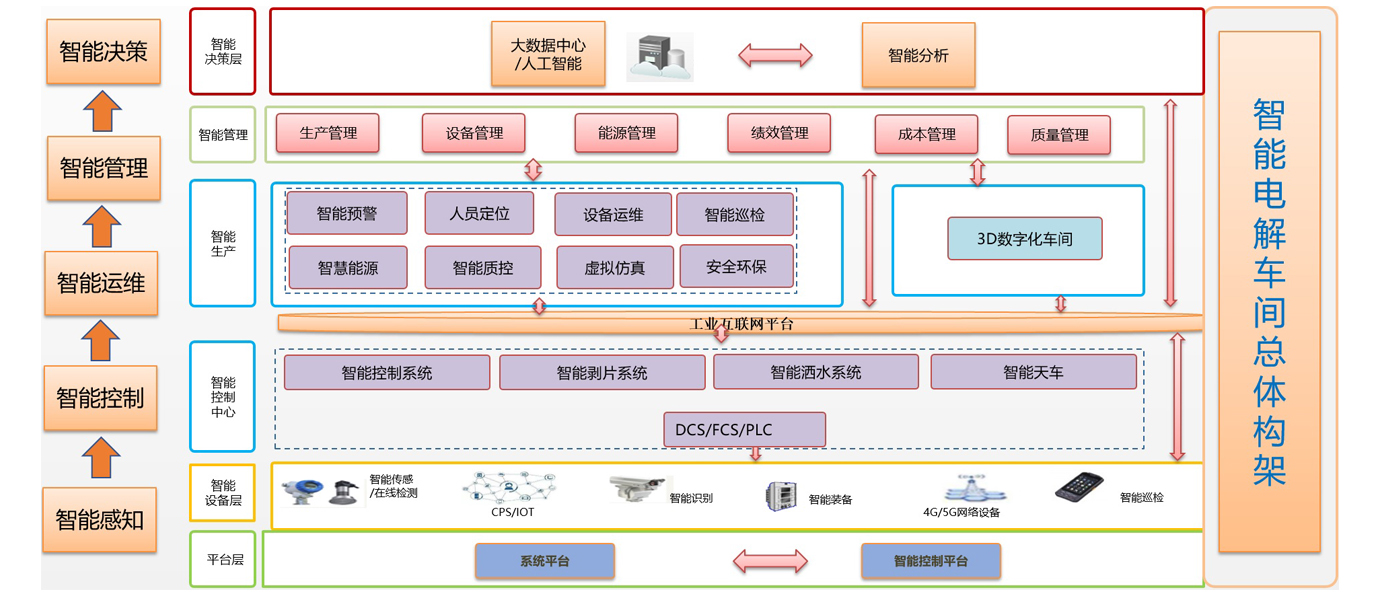

The plan adopts the GS-IEIS1000 electrolysis workshop intelligent interactive information system, and the system uses intelligent monitoring and Early warning, information-based intelligent management is the core and carrier, deeply integrating production management information and real-time production process information, and through the visual management of the production process and the automatic collection, mining and analysis of production real-time data, it effectively improves the level of production operation and decision-making. At the same time, through the establishment of a systematic operation strategy, production reliability, safety and economy are improved, and an efficient and reliable intelligent manufacturing model is established. Focusing on production equipment, intelligent perception, basic network, information system, cloud platform and other elements, adopt the cloud, edge and end architecture based on the industrial Internet to establish a two-level business management control system of "platform collaborative operation and factory intelligent production" , To use a large number of enterprise information systems based on traditional IT architecture as the data source of the industrial Internet platform, continue to tap the potential value of the system, and gradually promote the cloud deployment of traditional information services, build an enterprise intelligent manufacturing solution platform, and realize integrated intelligence in the workshop Production control, intelligent collaborative management, intelligent decision-making and new manufacturing model innovation.

System architecture diagram

3. Main functions

● Workshop quality management, workshop maintenance management, workshop energy management, workshop equipment management, workshop cost management , w orkshop performance management, workshop safety management, workshop environmental protection management and other related data; provide standardized interfaces for accessing other information systems to realize the complete connection of workshop data;

● The electrolytic cell fault detection system, the electrolytic workshop intelligent information management platform and other extensible data sources Obtain the data, after the data enters the large-screen controller, after data cleaning, analysis, processing and processing, modular display on the large screen;

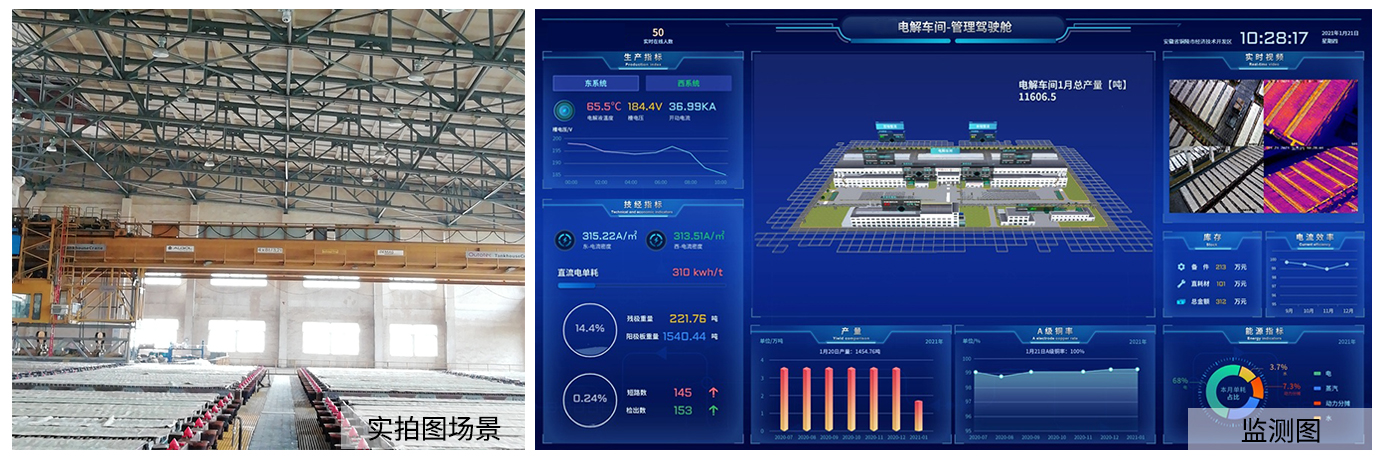

● based on web graphics engine software development, including panoramic 3D model modeling of electrolysis workshop, key equipment virtual simulation, dynamic association of important real-time data;

● System operation status indication, on-site visible light and infrared heat map display, detection data storage, equipment abnormality alarm, automatic detection area and inspection plan setting, etc.; faulty plate distribution display, faulty plate processing record management, tank group maintenance status management, electrolytic copper cycle management, group statistics and reports;

● Infrared thermal imaging auxiliary diagnosis, faulty plate processing and recording, and faulty plate real-time display;

● Wireless industrial Ethernet equipment adopts 802.11a/b/g/n/ac standard outdoor wireless base station (smart AP equipment) realizes the Wifi wireless communication coverage of the whole workshop, and establishes the foundation for the information transmission of intelligent production;

● The WiFi personnel positioning system is based on wireless AP, WiFi positioning tags, and WiFi network-side positioning algorithms. Real-time location and track query of personnel within the wireless coverage of the whole workshop;

4. Value

● Replace uneffectual work in the harsh environment of the traditional production site with a new generation of intelligent sensing;

● A multi-source heterogeneous data platform for real-time databases and relational databases, solving the interconnection of different data sources Intercommunication issues to realize enterprise data-based intelligent operation;

● Based on VR technology, establish a 3D digital model of the whole workshop, link real-time data of production and process, and provide a technical basis for later workshop intelligent management and decision-making;

● Using a strong and flexible integrated display and interaction system, providing the best human-computer interaction functions for different application roles, realizing global and sub-module business analysis, interaction, and realize paperless work;

● Through the configuration of the production management cockpit (large screen system), it can meet the requirements of single-screen or multi-screen spliced ultra-high-resolution data display and help enterprises build an overall large screen to display data;

● By building a digital integrated management platform integrating intelligent detection, wireless industrial Ethernet, integrated information interaction, large-screen integrated display, 3D workshop, and intelligent mobile applications, progress has been made in the smart electrolysis workshop in the traditional metallurgical industry.

5. Application case

更多案例

Consult now

If there is any need, we will arrange personnel to contact you as soon as possible

CONTACT US

Address: No. 228, Wanshui Road, High-tech Zone, Hefei City, Anhui Province

Hotline:400-805-8899

Service line:800-868-2578

Tel:0551-65324828

Scan and follow us

Copyright © 2021 Hefei Glod Star M&E Technical Development Co.,Ltd 皖ICP备05013787号-2

400-805-8899

400-805-8899

点击咨询

点击咨询